1. Characteristic Impedance and Signal Integrity

The 50 Ohm Coaxial Cable is specifically designed with a characteristic impedance of 50 ohms, which is the industry standard for most RF and microwave communication systems. Maintaining a consistent characteristic impedance is critical because even minor deviations can cause signal reflections, standing waves, and insertion loss, which compromise the efficiency and accuracy of high-frequency transmissions. The cable achieves this through precise engineering of the inner conductor diameter, dielectric thickness, and outer shielding geometry. Tight manufacturing tolerances ensure that the impedance remains stable across the entire cable length, providing reliable power transfer and minimal signal distortion. In high-frequency applications such as radar, satellite communication, and laboratory test systems, this impedance stability is essential for accurate measurements and consistent system performance.

2. Dielectric Material and Signal Propagation

The dielectric material separating the inner conductor from the shield is one of the most critical factors influencing high-frequency performance. Low-loss dielectric materials such as PTFE (Teflon), polyethylene, or foamed polyethylene minimize signal attenuation and maintain a stable velocity factor, ensuring predictable signal propagation times. The dielectric’s properties also influence the capacitance per unit length of the cable, which directly affects phase stability and signal integrity in high-frequency environments. For applications requiring precise timing or phase coherence—such as phased-array antennas or microwave measurement setups—the choice of dielectric material ensures that signals maintain their waveform characteristics with minimal distortion, even at multi-gigahertz frequencies.

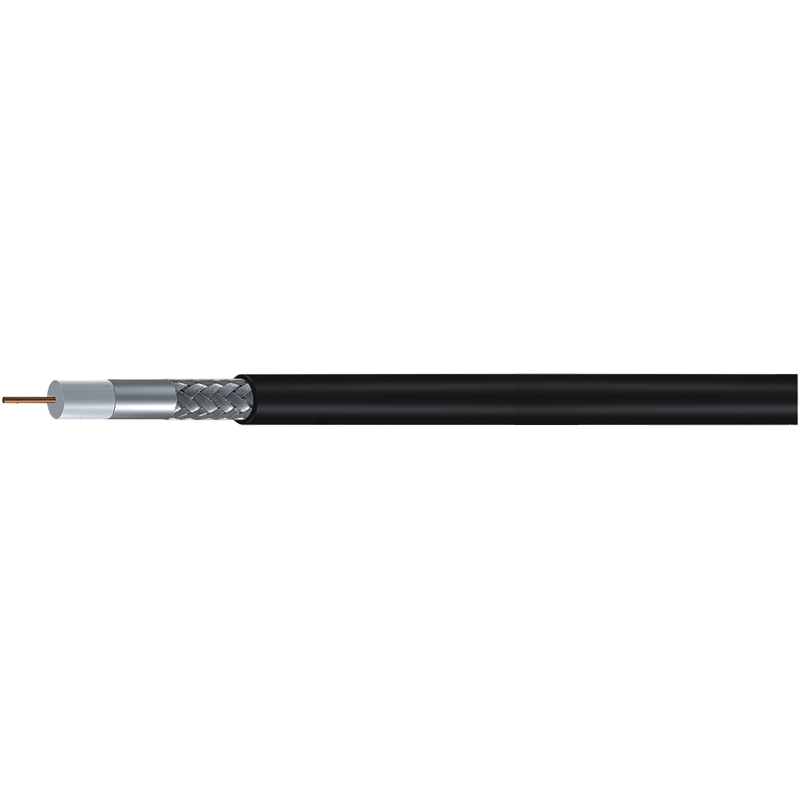

3. Shielding and Electromagnetic Interference (EMI) Protection

At high frequencies, signals are particularly susceptible to external electromagnetic interference (EMI) and radio-frequency interference (RFI), which can introduce noise and degrade the signal-to-noise ratio. The 50 Ohm Coaxial Cable addresses this by using a multi-layer shielding system, often comprising braided copper, aluminum foil, or a combination of foil and braid. This shielding prevents external electromagnetic fields from coupling into the inner conductor and simultaneously reduces radiation from the cable itself. High-quality shielding is essential in environments with multiple RF sources or sensitive equipment, as it maintains signal fidelity by minimizing crosstalk, leakage, and external interference that could otherwise compromise high-frequency transmissions.

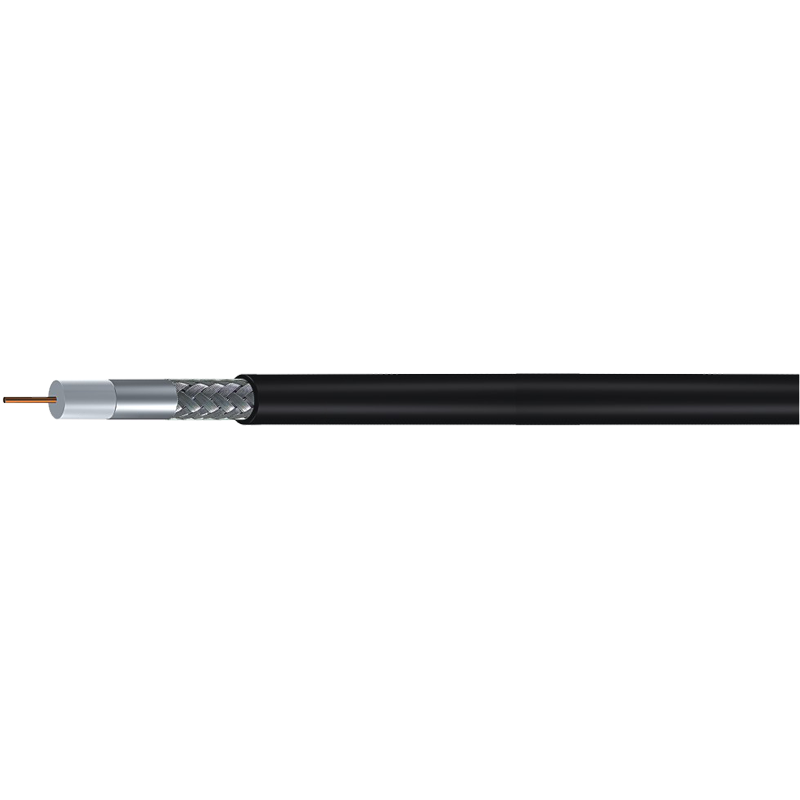

4. Attenuation and High-Frequency Loss

High-frequency signals naturally experience greater attenuation due to skin effect in the conductor and dielectric losses in the insulating material. The skin effect causes alternating current at RF and microwave frequencies to concentrate near the surface of the conductor, making the conductor’s surface finish and material conductivity critical for low-loss performance. 50 Ohm Coaxial Cables mitigate these losses by using high-purity copper or silver-plated conductors, which provide excellent conductivity and minimize resistive heating. The choice of low-loss dielectric also reduces energy dissipation within the insulator, ensuring that even over longer runs, the cable maintains sufficient signal amplitude and preserves waveform integrity. This makes the cable suitable for demanding high-frequency applications such as laboratory measurements, satellite links, and communication systems.

5. Power Handling and Thermal Management

High-frequency signals, especially in high-power RF or microwave systems, can generate heat due to resistive and dielectric losses. The 50 Ohm Coaxial Cable is designed to handle specified power levels safely, ensuring that impedance and signal integrity remain stable during operation. Proper conductor sizing, high-quality dielectrics, and durable outer jackets enable efficient heat dissipation, preventing local hot spots that could alter impedance or damage the insulation. Adhering to power ratings is essential, because exceeding them can lead to dielectric breakdown, signal distortion, or permanent cable failure. In professional applications, reliable thermal management ensures consistent performance under continuous or high-duty-cycle operation.