The outer jacket of fire-resistant alarm cables is constructed from high-strength, durable materials such as thermoplastic or thermoset polymers. These materials are chosen for their ability to resist cracking or breaking under stress. The tough jacket ensures that the cable can withstand physical handling during installation, especially in tight or confined spaces, where bending or twisting may be required. It also protects the inner components of the cable from mechanical forces that could otherwise cause damage, such as abrasion from rough surfaces or external impact.

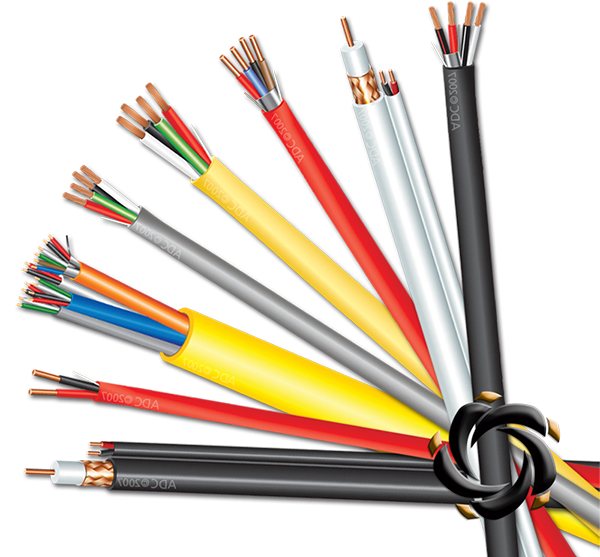

The internal conductors of fire-resistant alarm cables consist of flexible copper or tinned copper strands, which allow the cable to flex without losing electrical integrity. This flexibility helps the cable to bend, twist, and move along complex pathways during installation without damaging the conductive elements. It also ensures that the cable maintains its full electrical functionality throughout its operational life, even if it is exposed to slight mechanical stress from environmental conditions or equipment vibrations. The use of multi-strand conductors, as opposed to a single solid conductor, further enhances this flexibility, making the cable more resistant to mechanical stress while maintaining a consistent signal transmission.

Fire-resistant alarm cables are equipped with strain relief features to absorb and distribute mechanical stresses. These features can include reinforced cores or additional protective layers that help prevent stretching or kinking of the cable during installation. Strain relief minimizes the risk of damage to the internal conductors or insulation when the cable is subjected to bending, pulling, or twisting. This is particularly crucial when cables are installed in areas prone to mechanical movement, such as where they may be pulled or moved during routine maintenance, or exposed to vibration in industrial or high-traffic environments.

To further protect against mechanical damage, fire-resistant alarm cables feature additional layers of impact-resistant sheathing. This outer layer provides a barrier that prevents physical harm to the cable, such as cuts, abrasions, or crushing. The sheathing can be made from specialized materials that not only resist impacts but also enhance the overall durability of the cable. In some cases, the sheathing is made from metal or braided wire, adding another level of protection in environments where cables are exposed to harsh conditions or where accidental damage is a concern, such as in construction sites or industrial facilities.

In environments where fire-resistant alarm cables are exposed to vibration—such as mechanical rooms, transportation hubs, or areas with heavy equipment—these cables are designed to resist the effects of movement without losing their functionality. The combination of flexible conductors, durable insulation, and tough sheathing allows the cables to absorb vibrations while maintaining their signal integrity. This resistance to vibration ensures that the cable can continue to operate effectively in dynamic environments, where constant movement could otherwise lead to wear or failure in standard cables.

Fire-resistant alarm cables are engineered to operate efficiently not only under extreme temperature conditions but also when subjected to mechanical stress. The materials used in the insulation and outer jacket are selected for their ability to withstand both heat and mechanical forces without degrading. This synergy between fire resistance and mechanical resilience ensures that the cable continues to function reliably even when exposed to both high temperatures and physical stress simultaneously. Such performance is crucial in critical applications like fire alarm systems, where maintaining functionality during a fire and subsequent conditions is paramount.