The inner conductor of a 50 Ohm Low Loss RF Coaxial Cable is constructed from high-conductivity materials such as copper or silver-plated copper. These materials are selected for their low electrical resistance and excellent signal transmission characteristics. Copper is the most common material due to its high electrical conductivity, while silver-plating further enhances conductivity by reducing skin effect at higher frequencies. This ensures lower resistance and significantly reduced signal attenuation, making the cable suitable for long-distance signal transmission without substantial loss in power or signal quality.

The cable's dielectric insulation, which separates the inner conductor from the outer shield, is precisely engineered to maintain a consistent dielectric constant. This constant is crucial in controlling the speed and integrity of the signal transmission. Polyethylene, Teflon (PTFE), and foam-filled PVC are common materials used for the insulation. These materials are carefully selected for their low dielectric loss, meaning they absorb minimal energy from the signal. This characteristic is essential in reducing signal degradation and preserving both signal strength and phase accuracy, especially over long cable lengths.

The choice of low-loss dielectric materials directly impacts the overall performance of the cable in minimizing attenuation. Materials such as foamed polyethylene and Teflon (PTFE) are designed to ensure that the signal travels through the cable with minimal energy loss. These low-loss materials also help to prevent any form of signal distortion caused by the dielectric itself, ensuring that the original signal remains intact during transmission. Teflon and foamed polyethylene also provide excellent temperature stability and can handle a broad range of environmental conditions, further ensuring consistent performance.

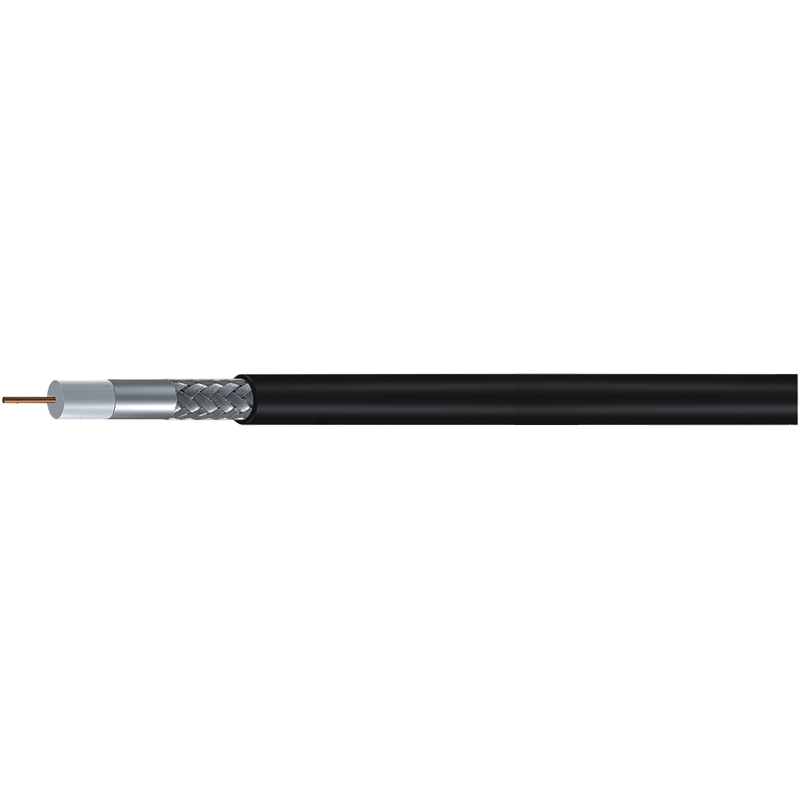

To maintain signal quality, the shielding in a 50 Ohm Low Loss RF Coaxial Cable plays a critical role in preventing external interference such as electromagnetic interference (EMI) and radio-frequency interference (RFI). The shielding is typically made from braided copper, aluminum foil, or a combination of both. This shielding effectively blocks external noise, ensuring the signal is not disturbed by nearby electronic devices. The performance of the cable is therefore maintained even in environments where there may be high levels of electromagnetic pollution, such as industrial or telecommunications settings.

Impedance matching is crucial for preventing signal reflections that can occur when the cable impedance does not align with the source and load impedances. A 50 Ohm Low Loss RF Coaxial Cable is designed with a characteristic impedance of 50 ohms, which is the most common standard for RF applications. Ensuring this impedance match reduces signal reflections that could lead to signal loss, phase distortion, and performance degradation. The cable’s internal construction, including the spacing between the inner conductor, dielectric, and outer shield, is engineered to maintain this precise impedance over long distances, preserving signal quality and reducing return loss.

The construction of the inner conductor—whether it’s solid or stranded—affects the cable’s signal transmission performance. Solid-core conductors are used for applications requiring longer cable runs, as they provide better signal integrity and lower resistance. Solid cores ensure that the signal travels with minimal attenuation over long distances. Stranded cores, while more flexible and easier to bend, may result in slightly higher attenuation over long distances due to the increased resistance from the individual strands.