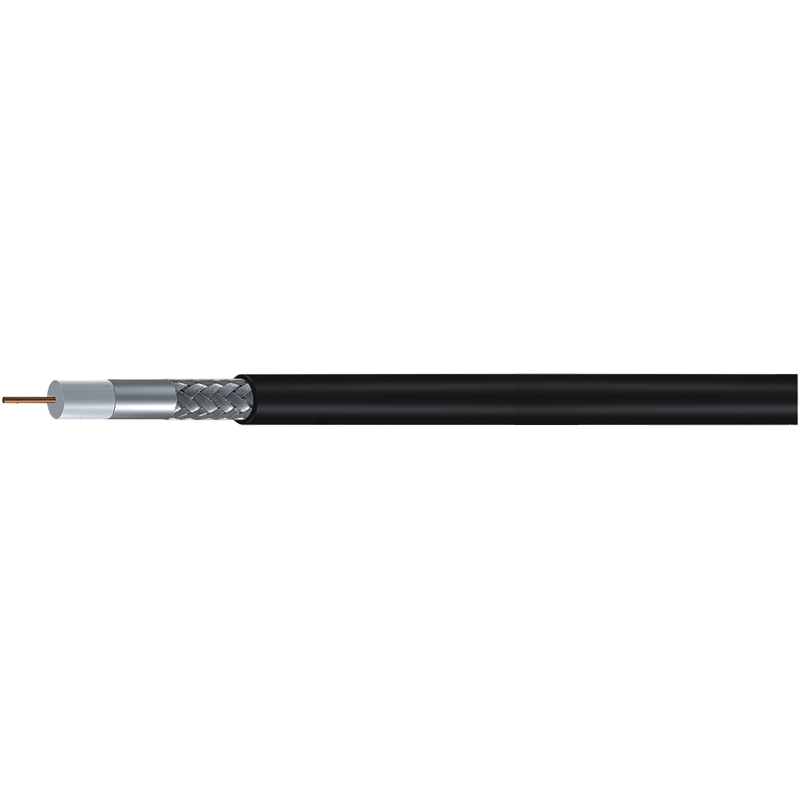

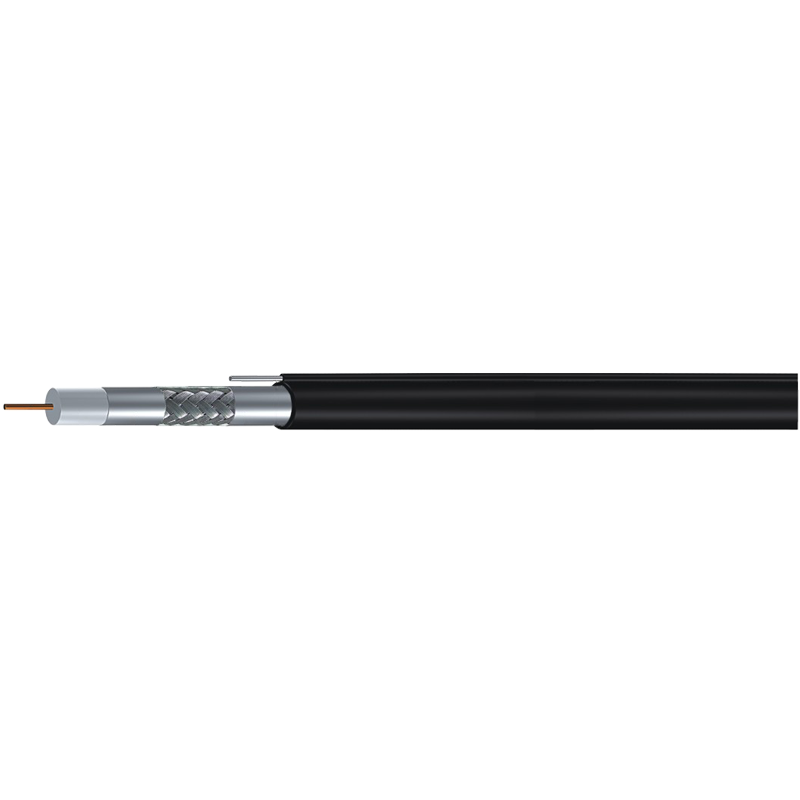

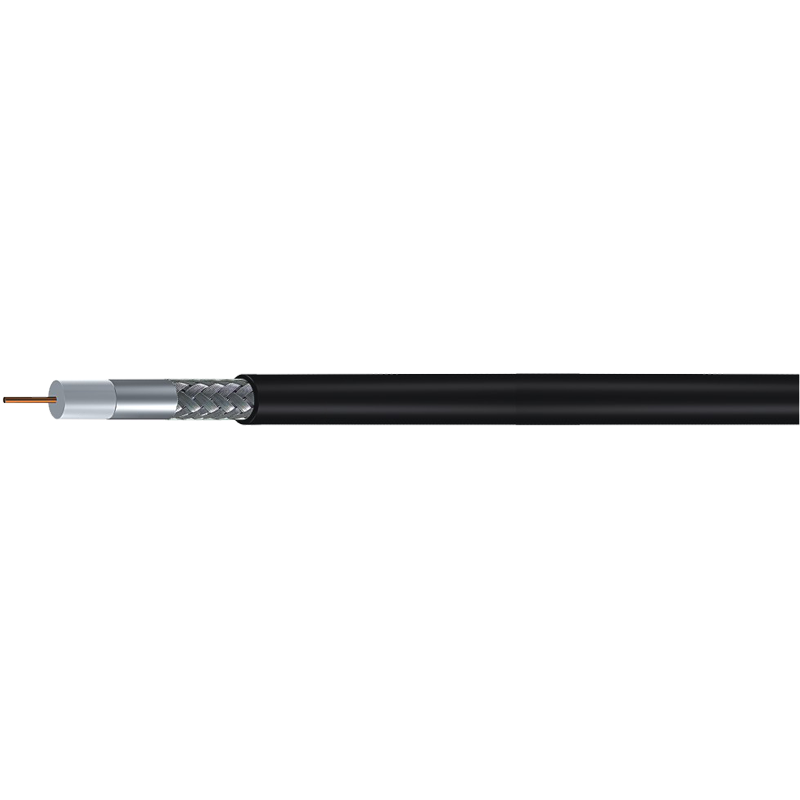

Communication Cables incorporate multiple types of shielding materials to act as physical and electrical barriers against external electromagnetic interference. Common shielding types include braided copper mesh, aluminum foil, or a combination thereof, each serving a specific function. The braided copper mesh provides mechanical strength and flexibility while delivering high coverage against low-frequency EMI. Aluminum foil shields offer near 100% coverage and are particularly effective at blocking high-frequency interference. The combination of these shielding layers in a single cable—known as dual or composite shielding—enables comprehensive protection across a broad spectrum of EMI sources. The quality, density, and continuity of these shield layers are carefully engineered to minimize signal degradation by reflecting or absorbing unwanted electromagnetic energy before it can penetrate the cable’s core conductors.

Grounding forms a critical component of EMI mitigation in Communication Cables by providing a low-resistance path to earth for any electrical noise induced on the shield. To facilitate this, cables include a dedicated grounding conductor or drain wire that runs alongside the signal conductors and is electrically bonded to the shielding material. This grounding conductor is connected to a reliable ground point at termination ends such as patch panels, racks, or equipment housings. Proper grounding prevents the accumulation of induced currents within the shield and ensures that EMI is safely dissipated. Inadequate or improper grounding can result in shield currents creating additional noise or causing signal distortion, undermining the shielding’s effectiveness.

Many Communication Cables, especially those used in data networking such as Category 5e or Category 6 cables, employ twisted pair conductor geometry. Each pair of insulated copper conductors is twisted at a specific pitch to ensure that any external electromagnetic interference affects both wires of the pair equally but in opposite directions. This design enables the use of differential signaling at the receiver end, which effectively cancels out the induced noise, significantly improving immunity to crosstalk and EMI. The twist rate may vary between pairs to reduce inter-pair interference further. This inherent noise rejection capability of twisted pairs reduces reliance on shielding alone and enhances overall cable performance in electrically noisy environments.

Beyond physical shielding and conductor arrangement, Communication Cables rely on high-quality dielectric materials to electrically isolate individual conductors and maintain signal integrity. The dielectric insulates the wires from one another and from the shield, controlling capacitance and impedance characteristics crucial for consistent signal transmission. Dielectric materials such as polyethylene (PE), fluorinated ethylene propylene (FEP), or low smoke zero halogen (LSZH) compounds are chosen for their stable electrical properties and resistance to environmental factors.

To maximize protection against electromagnetic interference spanning different frequency ranges, many Communication Cables utilize layered shielding designs. A foil shield offers continuous coverage that reflects high-frequency EMI, while a braided shield attenuates lower-frequency interference and provides mechanical durability. When combined, these layers complement each other by covering weaknesses inherent to a single shield type. For instance, a foil shield alone may be prone to physical damage or degradation in flexible installations, whereas a braid provides toughness and grounding continuity. This layered approach ensures that Communication Cables maintain high shielding effectiveness in diverse operating conditions, including industrial, commercial, and data center environments.