Superior Conductor Design and Material Quality

The 540 Trunk Coaxial Cable uses high-purity oxygen-free copper (OFC) or copper-clad aluminum (CCA) as its central conductor. This choice of materials is critical for reducing resistive losses, especially at high frequencies where the skin effect causes current to concentrate on the surface of the conductor. The 540 Trunk Coaxial Cable often employs conductors with precision-drawn diameters and smooth surfaces, which reduce microscopic surface irregularities that can scatter electrons and increase resistance. This results in lower insertion loss, particularly for signals above 1 GHz, allowing data to travel longer distances without requiring amplification. In contrast, standard coaxial cables often use lower-grade copper with higher impurity content, leading to increased resistivity and higher attenuation at similar frequencies. The material selection also impacts thermal conductivity, ensuring that the 540 Trunk Coaxial Cable remains stable in environments with high current flow or fluctuating temperatures, reducing the risk of performance degradation over time.

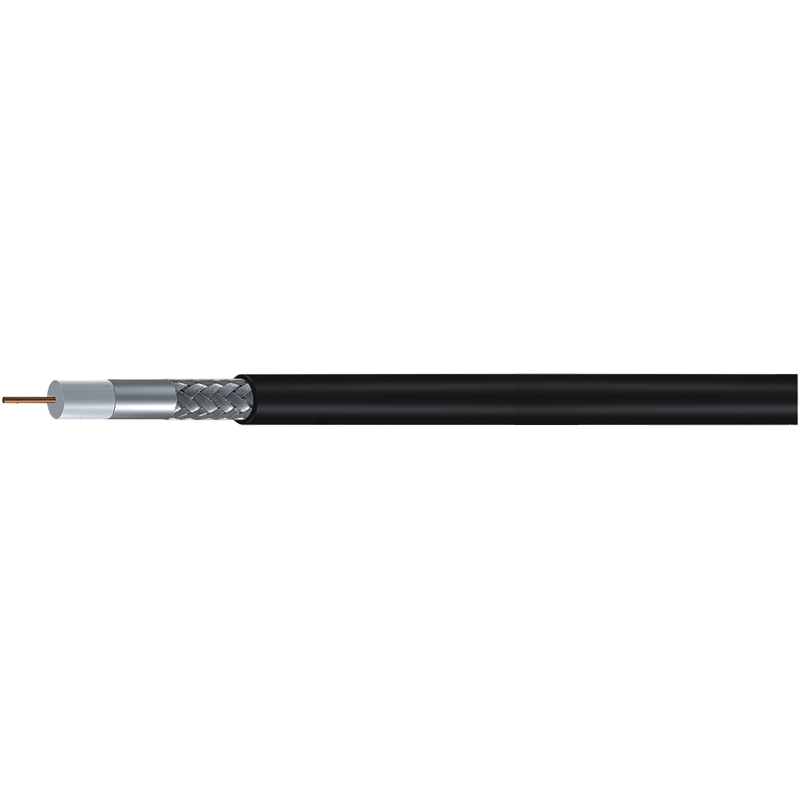

Advanced Shielding for Electromagnetic and Radio Frequency Interference

High-frequency signal transmission is highly sensitive to electromagnetic interference (EMI) and radio frequency interference (RFI). The 540 Trunk Coaxial Cable addresses this with a multi-layer shielding design, typically combining a dense braided copper shield with overlapping aluminum foil. This configuration creates dual protection: the braid provides mechanical flexibility and broad EMI shielding, while the foil layer offers 100% coverage against high-frequency interference. The tight weave and foil coverage ensure that crosstalk between adjacent cables is minimized, which is especially important in dense telecommunications racks or network trunks where multiple high-frequency lines run in parallel. Standard coaxial cables often rely on a single-layer braided shield or less dense foil, which may suffice for low-frequency applications but allows signal leakage and interference at higher frequencies. In addition, the 540 Trunk Coaxial Cable’s shielding design supports consistent grounding, further stabilizing high-frequency signal transmission and improving overall system reliability.

Low-Loss Dielectric for Enhanced Signal Integrity

The dielectric material in a coaxial cable determines how efficiently the signal propagates and how much energy is lost to the surrounding insulation. The 540 Trunk Coaxial Cable uses low-loss dielectric materials, such as foamed polyethylene (FPE) or PTFE (Teflon), which exhibit extremely low dielectric constant variation and minimal dissipation factor. This ensures that high-frequency signals maintain their amplitude and phase over long distances, reducing attenuation and signal distortion. The foamed dielectric also introduces small air pockets, lowering capacitance and allowing higher-speed signals to travel without degradation. Standard coaxial cables typically use solid polyethylene or PVC dielectrics with higher dielectric losses, resulting in signal attenuation, phase delay, and pulse distortion, particularly above 500 MHz. The 540 Trunk Coaxial Cable’s dielectric design also provides thermal stability, maintaining performance in high-temperature environments without significant changes in impedance or signal loss.

Consistent Impedance Control for Reliable Transmission

Characteristic impedance is critical for signal reflection management in high-frequency networks. The 540 Trunk Coaxial Cable is manufactured with tight impedance tolerances, usually within ±1% of the specified value (often 50 or 75 ohms), ensuring minimal Voltage Standing Wave Ratio (VSWR) and optimal power transfer. Any deviation in impedance can reflect energy back toward the source, causing signal loss and interference. The 540 Trunk Coaxial Cable maintains impedance consistency by precisely controlling conductor diameter, dielectric thickness, and shield spacing. In contrast, standard coaxial cables may have wider manufacturing tolerances, which can lead to localized impedance mismatches, particularly over long distances, degrading high-frequency performance. This consistent impedance ensures the cable can be used reliably in sensitive applications such as telecommunications backbones, CATV distribution, or high-speed data networks, where even minor reflections can disrupt service quality.

Enhanced Performance for Long-Distance Applications

Long-distance transmission of high-frequency signals is particularly challenging because signal attenuation increases with frequency and distance. The 540 Trunk Coaxial Cable combines its high-purity conductor, low-loss dielectric, and multi-layer shielding to minimize these losses, supporting trunk line applications over hundreds of meters without the need for repeaters in many cases. This makes it highly suitable for telecommunications backbone networks, broadcast infrastructure, and other systems requiring high signal fidelity over extended runs. Standard coaxial cables, by contrast, experience higher insertion loss, requiring signal amplification or regeneration at shorter intervals, which increases installation costs and network complexity. The 540 Trunk Coaxial Cable’s design ensures consistent signal amplitude, low jitter, and minimal distortion, which is essential for both analog and digital high-frequency signals, including HD video, broadband internet, and microwave communication links.