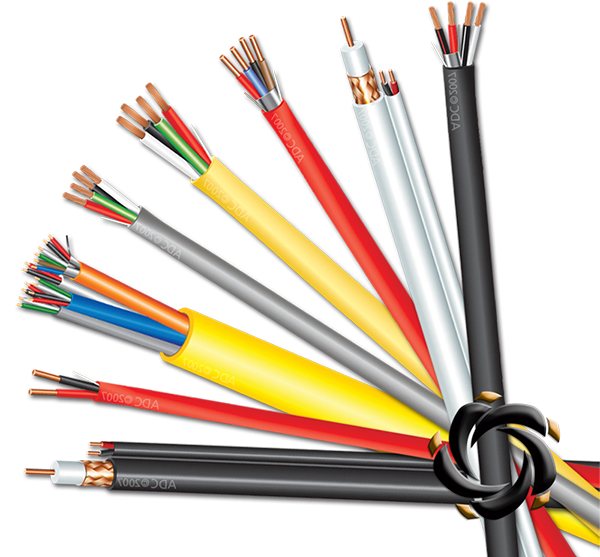

Conductor Design and High-Conductivity Materials

The inner conductor of 50 Ohm Coaxial Cable is typically made of high-purity copper or copper-clad aluminum (CCA) to ensure minimal resistive losses during high-current or high-frequency transmission. Copper’s low resistivity reduces I²R losses, which is crucial when transmitting high RF power. For extremely high-power applications, silver plating is sometimes used because silver has even lower surface resistance, particularly important at high frequencies due to the skin effect, which forces current to the outer layers of the conductor. The conductor’s diameter is carefully engineered to balance current-carrying capacity, voltage rating, and the characteristic 50 Ohm impedance. Optimizing conductor geometry ensures uniform current distribution, minimizing hotspots, and maintaining stable thermal and electrical performance over long cable runs.

Dielectric Material Selection and Thermal Management

The dielectric, which separates the inner conductor from the outer shield, is typically made from PTFE (Teflon), solid polyethylene (PE), or foamed polymers. These materials are chosen for their low dielectric loss, thermal stability, and high breakdown voltage. Low-loss dielectrics prevent excessive energy from converting into heat inside the cable, which is critical for high-power transmission. Foamed dielectrics reduce the material’s dielectric constant, lowering both signal attenuation and thermal accumulation. PTFE and similar materials maintain their mechanical and electrical properties even at elevated temperatures, preventing impedance shifts, insulation breakdown, or performance degradation under continuous high-power operation.

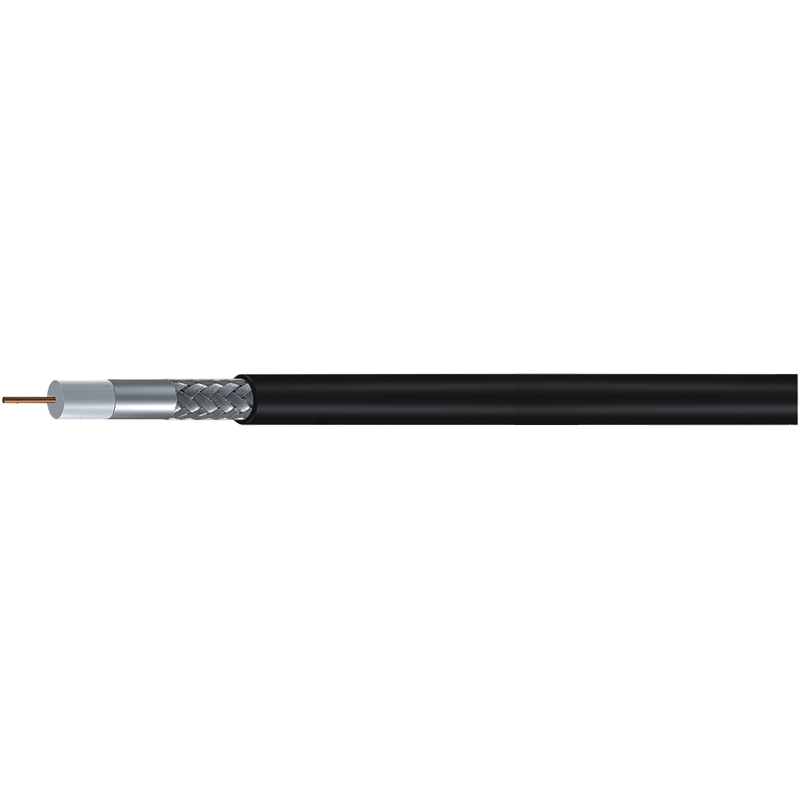

Shielding Design for EMI Protection and Heat Dissipation

The coaxial shield, often a braided copper, aluminum foil, or hybrid layered shield, serves two critical functions: shielding against electromagnetic interference (EMI) and aiding in thermal management. The shield conducts heat away from the inner conductor and dielectric, reducing localized temperature spikes that could damage the dielectric or jacket. Multi-layer shielding also distributes thermal and mechanical stresses evenly, preventing hot spots at connection points and along the cable run. The combination of braid density, foil thickness, and shield coverage is carefully optimized to balance RF performance, mechanical flexibility, and heat dissipation efficiency.

Outer Jacket Materials and Thermal Resistance

The outer jacket provides mechanical protection, UV resistance, chemical resistance, and additional thermal control. High-quality jackets are made from PVC, polyethylene, or low-smoke halogen-free (LSZH) compounds, which resist deformation under high heat generated internally or by environmental conditions. The jacket protects the cable from abrasion, moisture, and UV exposure, while facilitating heat transfer from the inner layers to the ambient environment. Advanced jacket materials also prevent thermal aging, maintaining flexibility and dielectric integrity over long-term high-power operation.

Impedance Matching and Signal Reflection Control

The characteristic 50 Ohm impedance of the cable is critical to avoid signal reflections that can concentrate energy at specific points, generating localized heating. Impedance mismatches create standing waves, which increase the voltage at certain points and can damage the dielectric or connectors. By precisely controlling the conductor diameter, dielectric thickness, and shield geometry, the cable maintains stable 50 Ohm impedance across its operating frequency range. This ensures efficient power transfer, minimal signal attenuation, and thermal stability, even in high-power transmission systems.

Adherence to Maximum Power Ratings

Each 50 Ohm coaxial cable has a specified maximum power rating, determined by the conductor size, dielectric thermal limits, shield design, and jacket material. Operating within this rating ensures that resistive heating and dielectric losses do not exceed safe thermal limits. Exceeding the rating can cause dielectric breakdown, jacket deformation, or signal distortion. Proper power rating adherence is critical to maintain thermal equilibrium, prevent cumulative heat buildup, and ensure long-term cable performance in high-power RF systems.