1. Braided Shielding: Flexibility, Mechanical Strength, and EMI Resistance

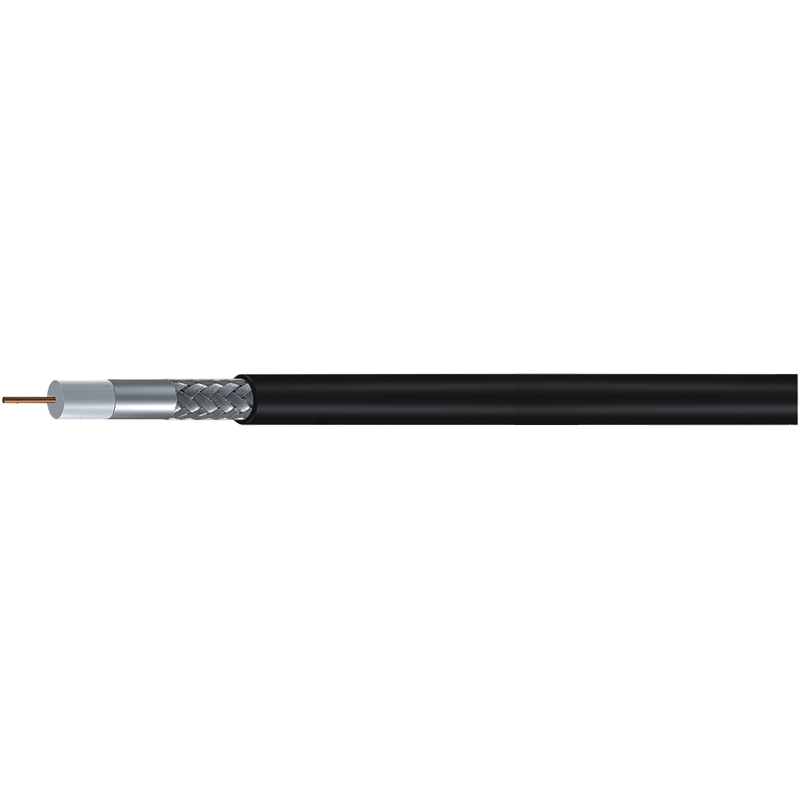

Braided shielding consists of fine metal wires, copper or tinned copper, woven into a mesh around the dielectric of the cable. The primary advantage of this design is mechanical flexibility, allowing the cable to bend or move without breaking the shield. Braided shields also contribute to structural durability, protecting the cable against physical stress during installation, maintenance, or everyday use.

From an interference perspective, braided shielding provides effective protection against low- to mid-frequency electromagnetic signals, as the tightly woven strands create a conductive barrier that absorbs and redirects unwanted currents. Coverage percentages typically range from 70% to 95%, with higher coverage improving EMI resistance but slightly reducing flexibility. However, due to the small gaps between strands, braided shields are somewhat less effective against high-frequency interference, where signals can partially penetrate the mesh. For applications that require frequent cable movement—such as mobile broadcast setups or CCTV cameras with rotating mounts—braided shielding provides a balance of durability and moderate EMI protection.

2. Foil Shielding: High-Frequency Interference Rejection

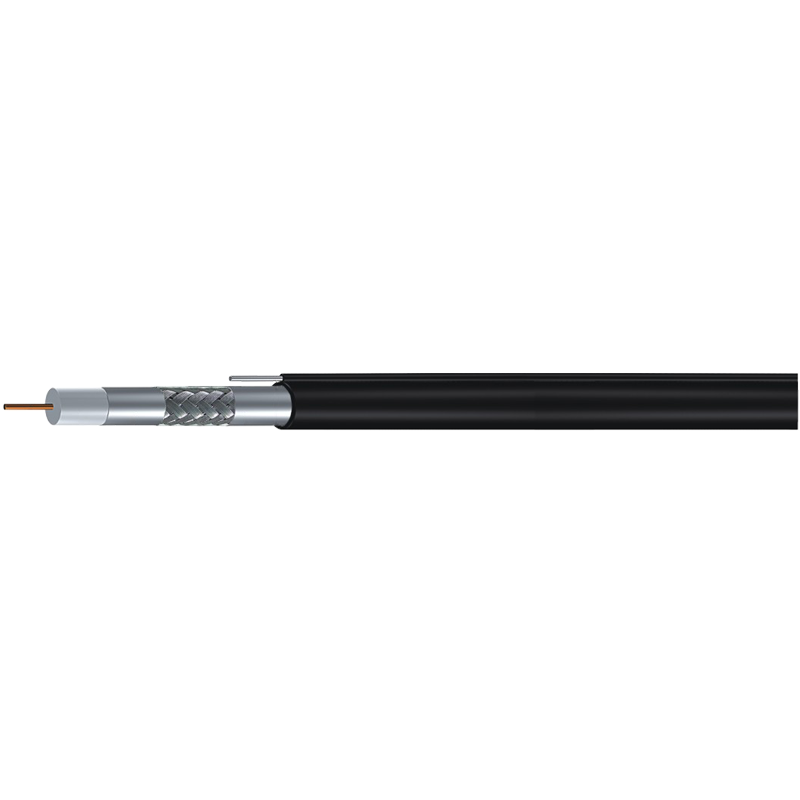

Foil shielding is composed of a thin layer of aluminum or aluminum-coated polyester wrapped continuously around the cable’s dielectric. The primary benefit of foil is 100% coverage, making it highly effective at blocking high-frequency electromagnetic interference. This level of protection is particularly critical for applications such as satellite television, broadband internet, or high-definition video, where even minor interference can result in noticeable signal degradation or data loss.

Foil shields are lightweight and have minimal impact on signal attenuation due to their continuous surface, which ensures that high-frequency signals encounter a uniform barrier. However, foil shielding is mechanically fragile; repeated bending, flexing, or physical compression can cause cracking or tearing, reducing its effectiveness. Therefore, foil-shielded 75 Ohm Coaxial Cables are best suited for static or semi-permanent installations where the cable remains relatively stationary, such as in-wall wiring, structured cabling systems, or rooftop satellite feeds.

3. Combination Shielding: Optimizing Performance and Durability

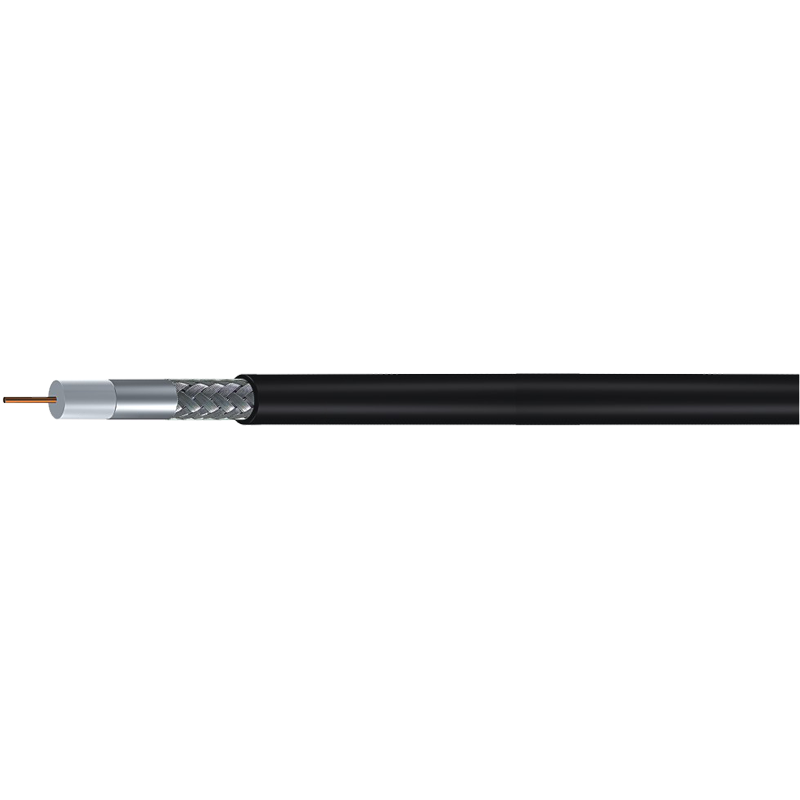

Combination shielding, also known as dual shielding, integrates the advantages of both braided and foil shields. In a typical design, the foil layer provides complete high-frequency interference rejection, while the braided layer adds mechanical strength and additional low-frequency EMI protection. This hybrid configuration ensures the cable performs reliably in high-interference environments, maintaining signal quality in both indoor and outdoor applications.

The combination shield also facilitates effective grounding, which is critical for maintaining characteristic impedance and minimizing reflections in long cable runs. In urban or industrial settings where multiple sources of EMI coexist—such as power lines, radio transmitters, and industrial machinery—dual-shielded 75 Ohm Coaxial Cables provide comprehensive protection, ensuring the transmitted signal remains clean and stable over extended distances.

4. Shielding and Signal Integrity

The effectiveness of shielding is directly tied to signal integrity, which encompasses signal-to-noise ratio (SNR), return loss, and overall transmission quality. Insufficient shielding can allow external electromagnetic fields to couple with the inner conductor, introducing noise, crosstalk, or data errors. A properly selected shield type maintains the cable’s 75 Ohm characteristic impedance, minimizing reflections and maximizing high-frequency performance. Dual shielding, in particular, reduces susceptibility to both high- and low-frequency interference, making it ideal for sensitive applications such as HD-SDI video transmission, high-speed data networks, and professional audio/video systems.

5. Installation Practices for Maximizing Shielding Performance

Even high-quality shielding can be compromised by poor installation practices. Users should avoid sharp bends, kinking, or crushing, which can damage foil layers or disturb braided coverage. During termination, the shielding must be correctly seated and grounded within the connector, ensuring continuous coverage from the cable’s entry point to the connection interface. Failure to do so can create gaps in the shield, resulting in signal leakage or vulnerability to external interference. In outdoor installations, weatherproofing, conduit protection, or UV-resistant jackets can further safeguard the shielding and extend cable longevity.

6. Selecting the Appropriate Shielding Type

The choice of shielding depends on the application requirements, environmental conditions, and frequency range:

-

Braided shielding is ideal for flexible or mobile applications where mechanical durability is prioritized over absolute high-frequency protection.

-

Foil shielding is suitable for stationary, high-frequency applications, providing maximum EMI rejection with minimal weight.

-

Combination shielding offers the best performance in complex environments, providing both high-frequency protection and mechanical resilience.

By understanding the strengths and limitations of each shielding type, users can optimize cable performance, reduce interference-related issues, and maintain high-quality signal transmission across all 75 Ohm Coaxial Cable applications.