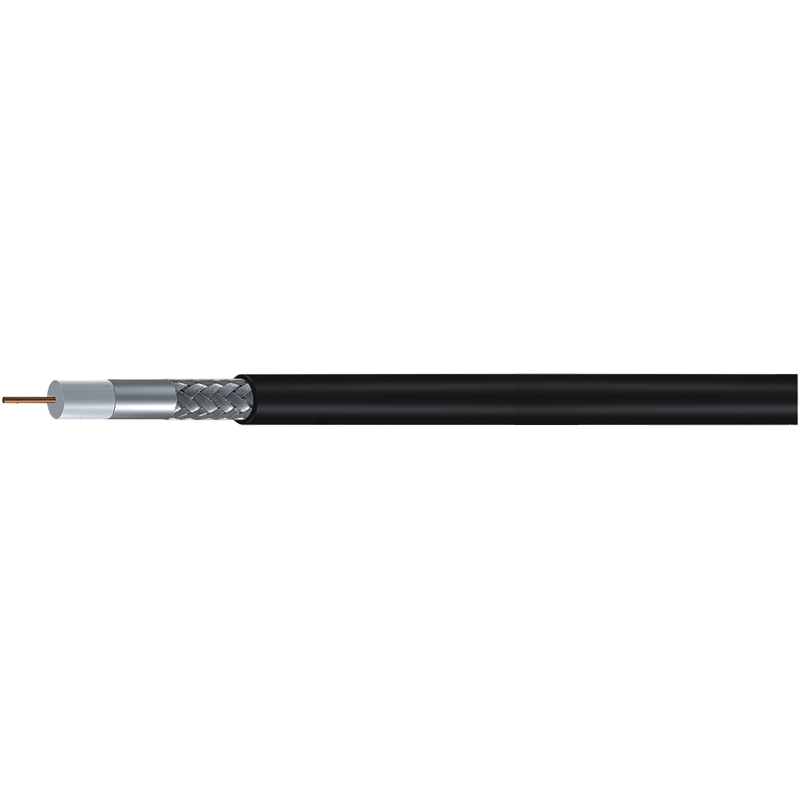

The shielding type in a 75 Ohm Coaxial Cable significantly affects its ability to block electromagnetic interference across various frequency ranges. Foil shields, made of a thin layer of metal such as aluminum, offer nearly complete coverage, creating an effective barrier against high-frequency electromagnetic waves. However, foil alone can be less effective at blocking low-frequency interference due to its relatively lower conductivity and flexibility. Braided shields, composed of interwoven metal strands, provide better attenuation of low-frequency noise thanks to their conductive pathways but rarely achieve full coverage, leaving small gaps that can allow some interference through. Combining foil and braid shielding results in a cable that offers comprehensive EMI protection by leveraging the high-frequency rejection of foil and the low-frequency conductivity and mechanical strength of braids.

Shield coverage percentage refers to the proportion of the cable’s circumference that the shield physically covers. Higher coverage, generally 95% or greater, minimizes the exposure of the inner conductor to external electromagnetic fields. In densely packed cabling setups, such as data centers or broadcast installations where many cables run in close proximity, near-total coverage is essential to prevent crosstalk and signal degradation. Lower coverage levels increase the risk that external noise from adjacent cables, electrical equipment, or ambient electromagnetic sources can penetrate the shield and degrade signal quality. High shield coverage also reduces signal leakage from the cable itself, which helps maintain system integrity and compliance with electromagnetic emission standards.

Cables that incorporate more than one shielding layer—combination of foil and one or two layers of braid—offer superior protection against a broad spectrum of electromagnetic interference. The outer braided shields are flexible and robust, providing mechanical durability and effective attenuation of low-frequency interference, while the inner foil shield offers consistent high-frequency attenuation with near-total coverage. This layered approach is particularly important in environments with mixed sources of interference, such as radio frequency signals, electrical noise from motors, or switching power supplies. The additional layers also reduce the likelihood of shield degradation over time, ensuring sustained EMI performance throughout the cable’s service life.

The type of metal used for shielding directly influences the cable’s effectiveness in rejecting EMI. Copper, commonly used for braided shields, offers excellent electrical conductivity and provides an efficient path to ground for interference currents. Aluminum foil is lightweight and cost-effective, offering high coverage but with lower conductivity than copper. The use of high-purity metals with good conductivity ensures minimal resistive losses and better attenuation of unwanted signals. The plating or treatment of shielding materials, such as tinning or silver plating, can improve corrosion resistance and maintain conductivity over time, which is crucial for maintaining shielding effectiveness in harsh environmental conditions.

The way the shielding is bonded to the cable’s dielectric and jacket impacts its physical stability and EMI protection. Bonded foil shields, where the foil is laminated directly to the dielectric layer, maintain consistent coverage even when the cable is bent or flexed, preventing gaps that could allow EMI ingress. In contrast, non-bonded foil can shift or wrinkle during installation, creating voids in coverage. Braided shields also require precise weave density and tension to avoid loosening over time, which can reduce coverage.