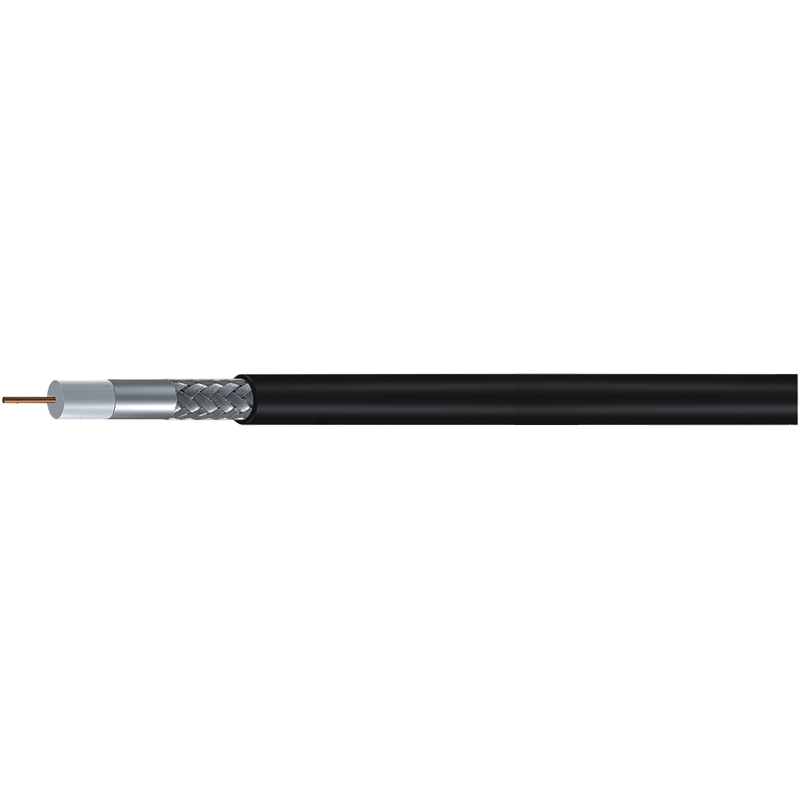

The outer jacket is the first line of defense against physical damage, providing a protective barrier for the internal components of 75 Ohm Coaxial Cable. The jacket material is selected based on its ability to resist abrasion, impact, UV degradation, and chemical exposure. Common materials include PVC (Polyvinyl Chloride), PE (Polyethylene), and LSZH (Low Smoke Zero Halogen). PVC is widely used due to its cost-effectiveness and durability against mild abrasion, chemicals, and UV exposure. However, in environments with higher physical stress or exposure to chemicals, Polyethylene or Teflon may be used, as these materials offer enhanced resistance to environmental factors. LSZH materials are typically used in indoor applications, where fire safety is crucial, as they emit fewer toxic gases when burned. The material choice impacts the overall resistance of the cable to external forces. For example, a thick PVC or PE jacket helps the cable endure physical wear and tear without compromising the integrity of the internal layers, making it suitable for environments where abrasion, weathering, or exposure to harsh conditions are expected.

Shielding is a critical component of 75 Ohm Coaxial Cable that not only protects against electromagnetic interference (EMI) but also provides added strength against mechanical stress. The braided shield, typically made of copper or aluminum, enhances the tensile strength of the cable, making it more resistant to crushing or pinching. The more densely woven the braid, the greater the protection it provides against physical forces, such as pulling or bending. This braided layer forms an additional barrier that safeguards the internal conductors and dielectric materials from impact, abrasions, and crushing. Furthermore, a foil shield in combination with the braid adds extra protection by ensuring minimal interference from external sources while enhancing the cable's resilience. In high-pressure or industrial environments, cables with double or triple shielding offer superior protection against both mechanical damage and EMI, making them more reliable in demanding installations where physical integrity is a concern.

The inner conductor of 75 Ohm Coaxial Cable typically consists of copper or copper-clad steel (CCS). Copper, with its excellent conductivity and flexibility, provides high-quality signal transmission, but it is relatively soft compared to CCS. Copper-clad steel combines the conductive properties of copper with the strength of steel, offering enhanced mechanical strength and resistance to stretching, kinking, or breaking under pressure. This is particularly useful in environments where the cable may experience significant physical stress, such as those involving movement or tight bends. The inner conductor’s resistance to mechanical damage depends on its construction; solid copper conductors are more prone to breaking if bent or crushed, while CCS conductors are more resilient and can withstand more physical abuse while still maintaining signal integrity. Therefore, the choice of material for the conductor affects how well the cable resists crushing, pulling, or other mechanical forces.

The dielectric material that separates the inner conductor from the shield plays a significant role in maintaining the cable's structural integrity. Materials like foam polyethylene (Foam PE), solid polyethylene, and Teflon are commonly used for dielectric insulation. The dielectric is designed to maintain the signal's impedance while also providing physical protection to the inner conductor. Foam PE, known for its low density, provides a good balance of electrical performance and mechanical resilience but can be more susceptible to compression in harsh conditions. On the other hand, solid polyethylene provides better resistance to crushing or physical damage, though it may not be as effective at signal transmission at higher frequencies as foam-based dielectric materials. Teflon, although more expensive, offers high resistance to both physical damage and extreme temperatures, making it ideal for environments where the cable may be subjected to harsh mechanical forces. The dielectric material contributes to the overall durability of the cable, as it helps maintain the proper shape of the cable and prevents deformation under pressure, which is crucial for retaining signal integrity.