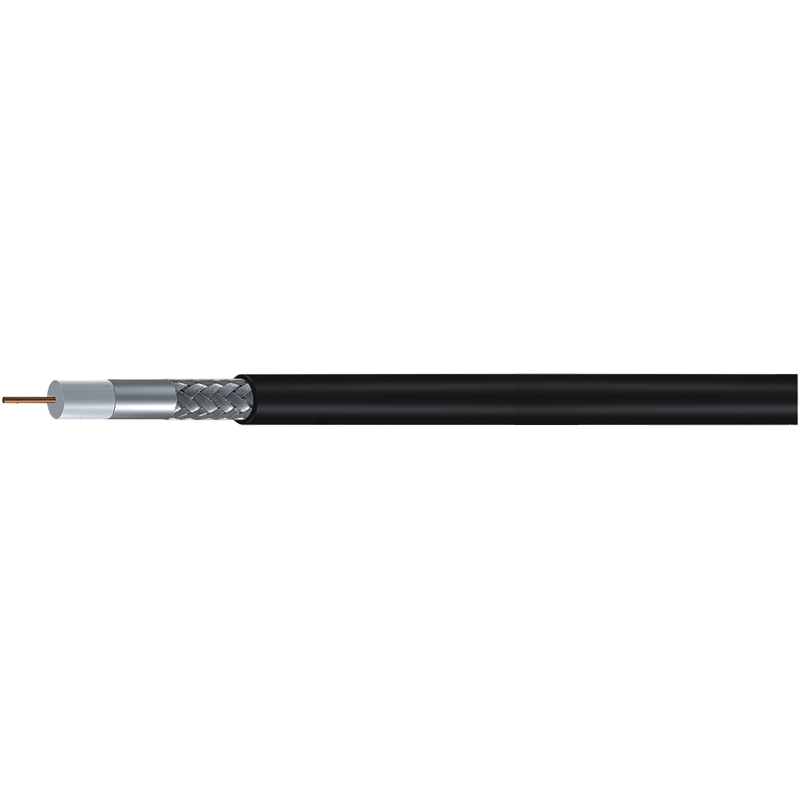

The 500 540 Trunk Coaxial Cable is built using high-conductivity copper or tinned copper for its central conductor. Copper is known for its excellent conductivity, which reduces the resistance in the transmission path. This makes copper an ideal material for high-power applications where minimal signal loss and heat generation are crucial. Copper’s high conductivity also ensures the cable can transmit power over longer distances without significant voltage drops, a common issue in cables with lower-quality conductors. The use of copper ensures that the 500 540 Trunk Coaxial Cable maintains its performance over time, even under heavy power loads. Additionally, the use of tinned copper can further enhance the cable's resistance to oxidation, ensuring long-term reliability even in harsh environmental conditions. In comparison, cables that use lower-grade conductors, such as aluminum, may not provide the same level of performance when dealing with high-power signals due to higher resistance and susceptibility to heat buildup.

The 500 540 Trunk Coaxial Cable is engineered to handle high-voltage signals without compromising insulation or safety. This capability is a result of the carefully selected dielectric insulation materials that separate the inner conductor from the outer shielding. These materials are designed to withstand significant electrical stress without breaking down, which is crucial in high-power applications where voltage levels can fluctuate. The dielectric material’s ability to resist electrical breakdown is a key factor in the cable’s ability to carry high-power signals without risk of short circuits or arcing. In comparison to other cables with lower dielectric strength, the 500 540 Trunk Coaxial Cable provides superior protection against insulation failure, making it a more reliable option in systems with high voltage requirements.

The 500 540 Trunk Coaxial Cable is specifically designed to minimize attenuation, which is the loss of signal strength as the signal travels through the cable. Attenuation becomes more pronounced in high-power applications, where the energy carried through the cable can cause greater signal degradation over distance. The construction of the 500 540 Trunk Coaxial Cable ensures that it maintains low attenuation even under high-power conditions. This is achieved through its high-quality dielectric materials, which reduce the overall energy loss and prevent the cable from becoming a source of distortion or signal degradation. The result is a reliable transmission of high-power signals over long distances without the significant performance loss that is often experienced with other cables. Cables that are not designed for high power may experience much higher levels of attenuation, causing performance degradation and potential damage to the system.

Shielding is one of the most important aspects of the 500 540 Trunk Coaxial Cable in terms of its ability to handle high-power signals. The cable features multiple layers of shielding, including braided wire and foil shields, which provide robust protection against electromagnetic interference (EMI) and radio-frequency interference (RFI). The shields act as a barrier that prevents external signals from interfering with the high-power signal being transmitted through the central conductor. At the same time, these shields prevent the high-power signal from radiating out of the cable, ensuring that neighboring cables or systems are not affected by electromagnetic leakage. The braided wire shielding provides mechanical protection while offering an efficient EMI shielding performance, and the foil shielding adds another layer of protection, especially in areas where the braided shield might have gaps. This dual-layer shielding is critical in high-power applications, where external interference or signal leakage could seriously compromise the integrity of the system.